When you walk across a carpet and feel that soft, cushioned comfort under your feet, there’s a lot of work that went into making that possible. One of the unsung heroes of the carpet manufacturing process is the foam backing. This foam provides the comfort and durability we love, but it wouldn’t be possible without precision-made rotors and stators in the mixing machines. These parts are essential to creating the foam, and the quality of the rotors and stators can make all the difference.

At DanThai Machinery, we specialize in producing high-precision rotors and stators, helping manufacturers achieve that perfect foam backing. But why does the quality of these parts matter so much? Let’s dive in.

Consistency is Key

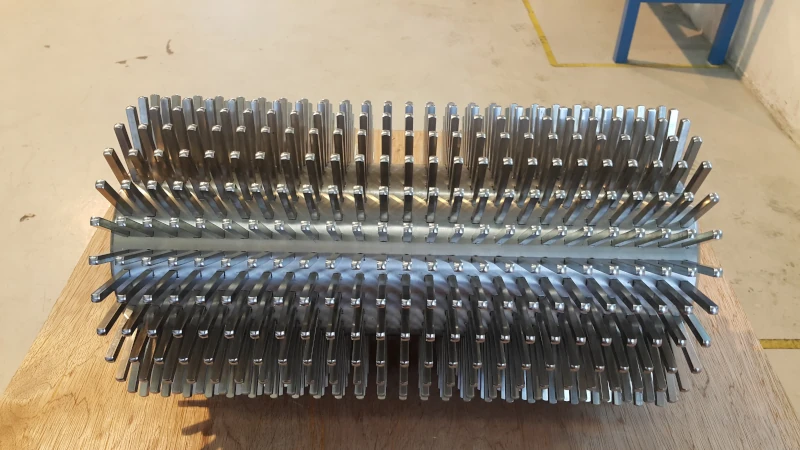

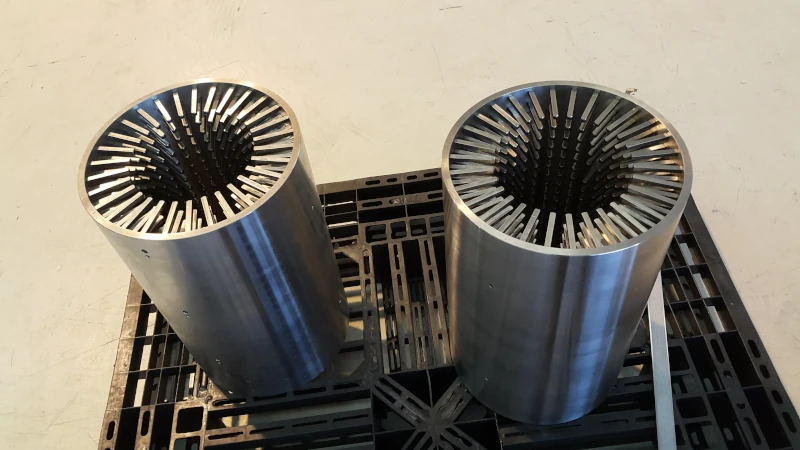

Foam backing has to be just right—too dense, and the carpet feels heavy and hard; too airy, and it won’t hold up over time. The rotor and stator in the mixer are responsible for achieving the right consistency. The rotor spins at high speeds, forcing the materials through the stationary stator, mixing them with air and creating that smooth, even foam.

But this process only works if the rotor and stator are made with precision. Even tiny imperfections can throw off the balance, causing the foam to come out uneven or inconsistent. That’s why every rotor and stator we make at DanThai Machinery is crafted to exacting standards. We ensure that our components are as smooth and aligned as possible, so the mixing process goes off without a hitch.

Making the Most of Your Equipment

You know that feeling when a piece of machinery just hums along, doing its job without fuss? That’s what you get with well-made rotors and stators. Not only do they help you create consistent foam, but they also make sure your equipment runs efficiently.

Poorly made parts create resistance in the system, making the machine work harder and use more energy. This can lead to higher operational costs and more wear and tear on your equipment. With precision-made rotors and stators from DanThai Machinery, your mixer will run smoother, last longer, and use less energy, saving you both time and money in the long run.

Built to Last

Speaking of lasting longer, let’s talk about durability. Rotors and stators take a lot of punishment in industrial mixers. They’re spinning at high speeds, dealing with high pressure, and constantly exposed to harsh materials. If they aren’t built well, they’ll wear out quickly, leading to costly downtime and repairs.

That’s why we use only high-quality materials and advanced manufacturing techniques at DanThai Machinery. Our rotors and stators are made to stand up to the demands of industrial foam production, so you can count on them to keep working, batch after batch.

Safety First

It’s easy to overlook, but safety is a big deal when it comes to industrial machinery. A poorly made rotor or stator can lead to imbalances or even failures, which could put your equipment—and your team—at risk. At DanThai Machinery, we take safety seriously. Every rotor and stator we make goes through rigorous testing to ensure it meets the highest safety standards. You can trust that our components will not only perform well but also keep your operations running safely.

Why DanThai Machinery?

At the end of the day, you need rotors and stators that you can rely on. That’s where we come in. At DanThai Machinery, we pride ourselves on delivering high-precision, high-quality components that make a difference in your production process. Whether you’re looking to improve your foam quality, extend the life of your machinery, or boost your energy efficiency, we’re here to help.

Contact us today to learn more about how we can support your business with top-notch rotors and stators. We’re always happy to answer any questions you have or provide more information about our products. At DanThai Machinery, we’re not just providing parts—we’re helping you create better carpets.

If you have any questions or need more details, don’t hesitate to reach out. We’re here to help make your manufacturing process smoother, safer, and more efficient!